What is geosynthetic clay liners? General introduction of GCL-3.

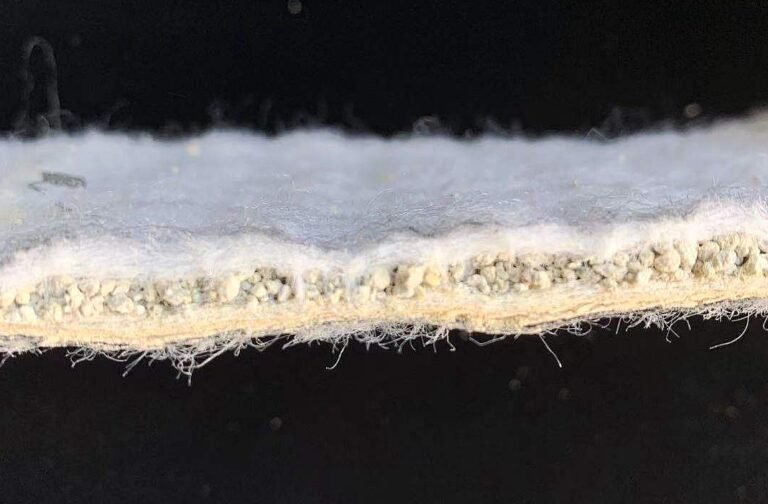

Geosynthetic clay liner is composed of 3 levels. The upper level and the lower level are woven geotextile and non woven textile. The middle level is bentonite grains, which are carefully selected crude and filled in between the two levels after special processing. The bentonite grain in GCL made by this method does not flow in a fixed direction. It distributes evenly and forms waterproof layer, owning excellent waterproof effect. This GCL is a kind of new green waterproof materials, which are widely applied in many waterproof construction projects. Bentonite is a volcanic clay mineral that formed naturally during the course of 200 million years under the influence of water and pressure. Only high quality bentonite in granular form is used for the manufacture of Geosynthetic Clay Liners.

What is geosynthetic clay liners? General introduction of GCL-4.

Geosynthetic clay liner can be applied separately, or combined with high density polyethylene (HDPE). Our GCL combines the two advantages together, not only containing all the properties of geotextile materials, but also bearing of double waterproof property.

GCL-4 consists of a layer of bentonite encapsulated between two geotextiles (a nonwoven and awoven polypropylene geotextiles), needle punched together and laminated on one side to apolyethylene membrane for maximum performances under a wide variety of field conditions. This integrated matrix of bentonite and needle punched fibers provides highshear strength and allows the GCL-4 to keep low permeability even in presence of adverse installation conditions. The GCL-4 has high internal shear strength characteristics for steep slope applications.

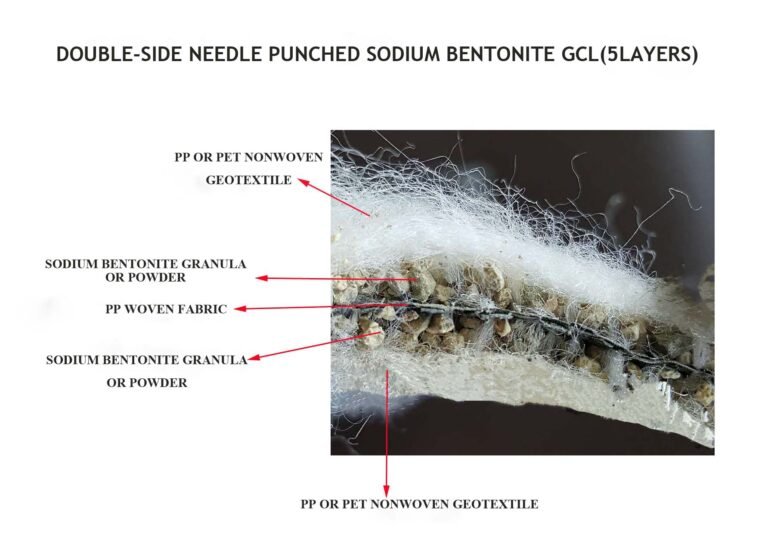

What is new developed geosynthetic clay liners? GCL-5

There are five layers from the top: nonwoven geotextile, sodium bentonite granular, PP woven fabric, sodium bentonite granular, and nonwoven geotextile. Both of the materials are needle punched together, and both sides of PP woven fabric are filled with bentonite granular. During the production process of 3 layers of GCL, when the upper surface of nonwoven geotextile is wrinkled, the quantity of bentonite granular will be reduced between woven and nonwoven geotextile. But for the double sides needle punched, when there is a winkled area, the lower layer will be filled with more bentonite granular, thus making up for the reduction of bentonite granular lose.

Advantages of Geosynthetic clay liners

Enviroment friendly

Excellent water sealing

Self-repairig effect

Cost- effective system

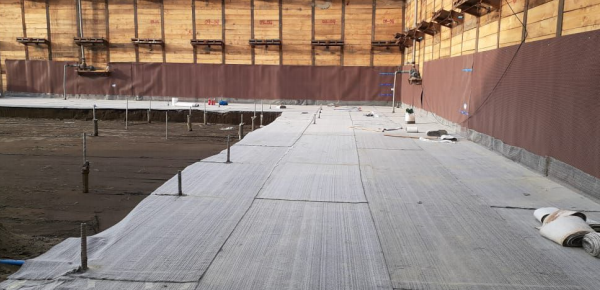

Geosynthetic Clay Liners Projects

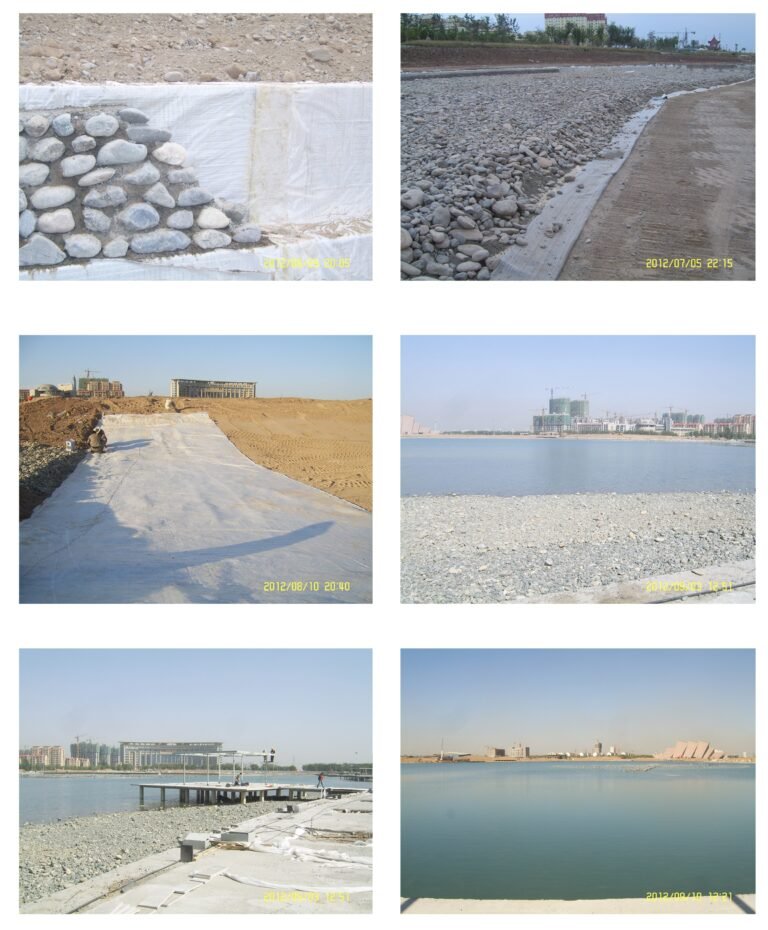

Dykes and Water Engineering Structures

Geosynthetic clay liners (GCL’s), are geosynthetic barriers used for various sealing and waterproofing applications in underground Mining and Civil Engineering.

Taian Hongyuan Seal Bentonite Mats are a composite consisting of two layers of geo-textiles filled with natural sodium bentonite.

The application range of Taian Hongyuan Seal Bentonite Mats comprises waterproofing, gas sealing, and usage as a vapor barrier. Bentonite mats are a proven and versatile sealing system that has been used in many construction projects around the world.

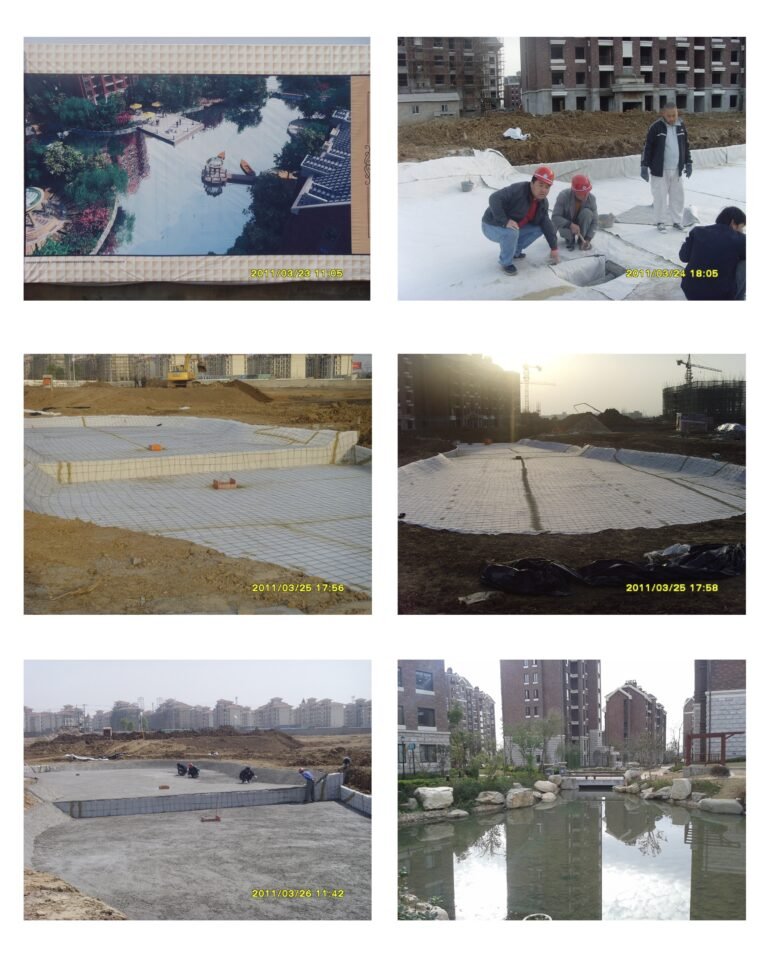

We have applied our Geosynthetic clay liners on artificial lakes for different parks all over the world. Both of the projects are very successful cases for us to refer.

Geosynthetic Clay Liners applied as landfill site liners

In order to avoid the risk of environmental hazards, waste material in landfill sites and waste disposal facilities must be stored permanently and safely. The relevant technical regulations specify suitable systems for sealing the base and upper surface of landfill sites. Geosynthetic clay liners are used in surface sealing systems, in the technical barrier, and in intermediate and temporary sealing layers.

The selection of a geosynthetic clay liner for use as a sealing element in a landfill site is made in accordance with the project-specific suitability assessment made by the relevant waste management authority. This certification of suitability is important because the clay liner forms an essential component in a coordinated sealing system.

Download information of Geosynthetic clay liners:

What is bentonite waterstop strips?

Water stop strips is a hydrophilic swelling bentonite waterstop. The based material is bentonite clay with polymer rubber. The product swell when contact with water create more than 300% expansion. The release benonite fill void between the two portion of concrete joint.

Where to use bentonite waterstop strips?

- Construction joints.

- Water tank, waste water tank.

- Tunnels.

- Basements.

- Elevator pits.

- Retaining walls.

- Pipe penetration.

- King post.

- Sheet pile joint.

- Precast concrete structure.

- Block out.

- Pile cap

How does bentonite waterstop strips work?

Waterstop strip is a sodium bentonite based waterstop designed to stop water infiltration through cast-in-place concrete construction joints by expanding upon contact with water to form a positive seal against the concrete. The key to strips effectiveness is its 75% sodium bentonite content, which provides superior expansion to seal and fill voids and cracks in the concrete. WATERSTOP is an active bentonite based waterstop that is designed to replace passive PVC/Rubber waterbars, thereby eliminating the requirement of special pieces, split-forming and seam welding.

How to apply bentonite waterstop strips on sites?

1. Clean and brush off dirts on concrete surface.

2. Place strips on joint and press to fix strips.