Waterstop belt and waterstop strip are widely used in various construction projects with waterproof requirements. However, many people do not know how to choose waterproof products that can fully meet their waterproof needs. Here, we briefly introduce their differences to help you better understand and choose the appropriate waterproof products.

Waterstop strip

Raw materials:

Polymer inorganic water absorbent materials, rubber, bentonite, and additives.

Waterproof principle:

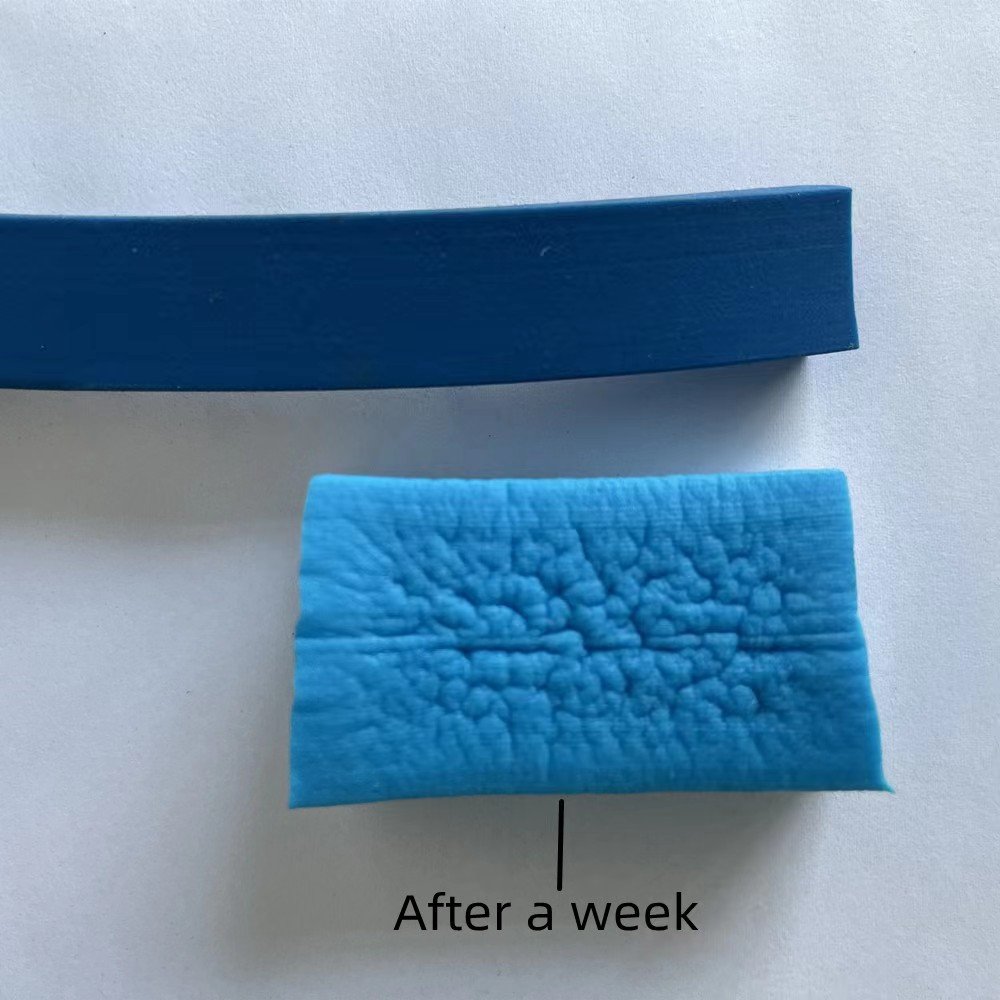

After being exposed to water, it can expand to bigger size to fill the gaps in the concrete, thereby achieving a waterproof effect.

Benefits:

Cheap and easy to construct. Size and shape can be customized.

Applications:

t is usually used for building parts with low waterproof requirements, such as basement exterior walls, foundation rafts, to prevent capillary water in the soil, and can not be exposed under the sunshine.

Water stop belt

Raw materials:

PVC or rubber

Waterproof Principle:

It is partially or completely embedded in the concrete during the pouring process to prevent water seepage.

Benefits:

High elasticity, good abrasion resistance, high tensile strength, good waterproof performance, and strong deformation adaptability. Shape and sizes can be customized easily.

Scope of Applications:

Suitable for construction joints, deformation joints, and settlement joints with large deformation.