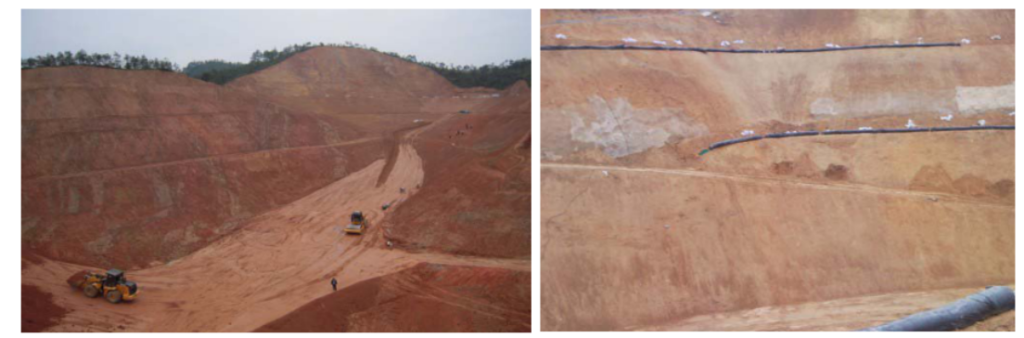

Ⅰ. Necessity of seepage prevention by geosynthetic clay liners

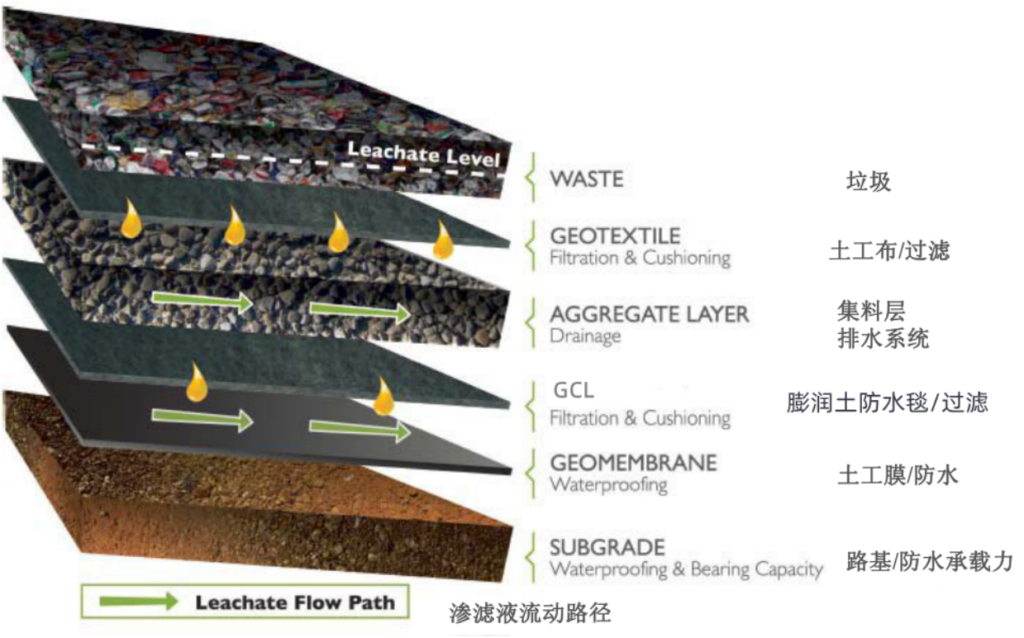

- Landfill refers to the garbage disposal site used for the treatment and disposal of all kinds of garbage and wastes, with geotechnical anti-seepage to prevent the leakage of garbage filtrate, with leachate treatment or treatment facilities and equipment, and with operation, management, maintenance and final closure meeting the sanitary requirements.

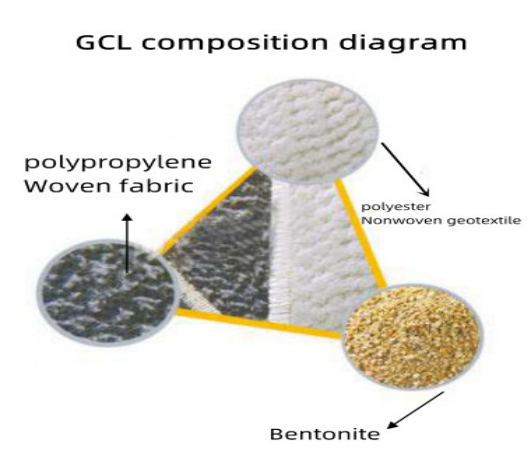

- Landfill is a complex and effective anti-seepage system composed of various geotechnical materials. The main materials include geomembrane, bentonite waterproof blanket, etc. Its function is to prevent contaminated liquid from seeping into the soil.

- Modern landfills need to use a large number of geosynthetics, hoping to get the most perfect anti-seepage system with the least investment, so as to achieve the maximum design capacity and lower operating costs. In order to protect the environment, bentonite waterproof blanket and geomembrane are an indispensable part of the landfill seepage control system.

Ⅱ. Single layer anti-seepage system

- The single-layer anti-seepage system of the landfill site has only one anti-seepage layer. Above the anti-seepage layer is a protective layer and a drainage layer. Sometimes a cushion layer and a groundwater collection system are set below the anti-seepage layer.。

- Single layer anti-seepage system has low cost, convenient construction and low safety factor. At present, the single-layer anti-seepage system is only recommended for landfill projects when the risk of groundwater pollution is extremely low (such as low toxicity of garbage, low groundwater level and good soil anti-seepage).

- In the design of single-layer anti-seepage system, single-layer geomembrane or Geosynthetic clay liner is generally used as the anti-seepage layer, and non-woven fabric is used as the protective layer.

1.The double-layer anti-seepage system consists of two anti-seepage layers, between which is a drainage layer to guide and drain the liquid or gas between the two anti-seepage layers. The protective layer and drainage layer are above the impervious layer, and the groundwater collection system can be set below the lower impervious film.

2.Generally speaking, the double layer anti-seepage system is recommended in the following cases:

(1)Safe landfill sites for hazardous wastes constructed in areas with strict safety facilities requirements;

(2) The natural soil layer of the foundation is very poor (k>10-5cm/s), and the groundwater level is high (less than 2m from the foundation bottom);

(3)Build a mixed landfill, i.e. a landfill for the joint disposal of domestic waste and hazardous waste;

(4)The cost of earthwork is very high. In contrast, the cost of HDPE film is lower than that of earthwork.

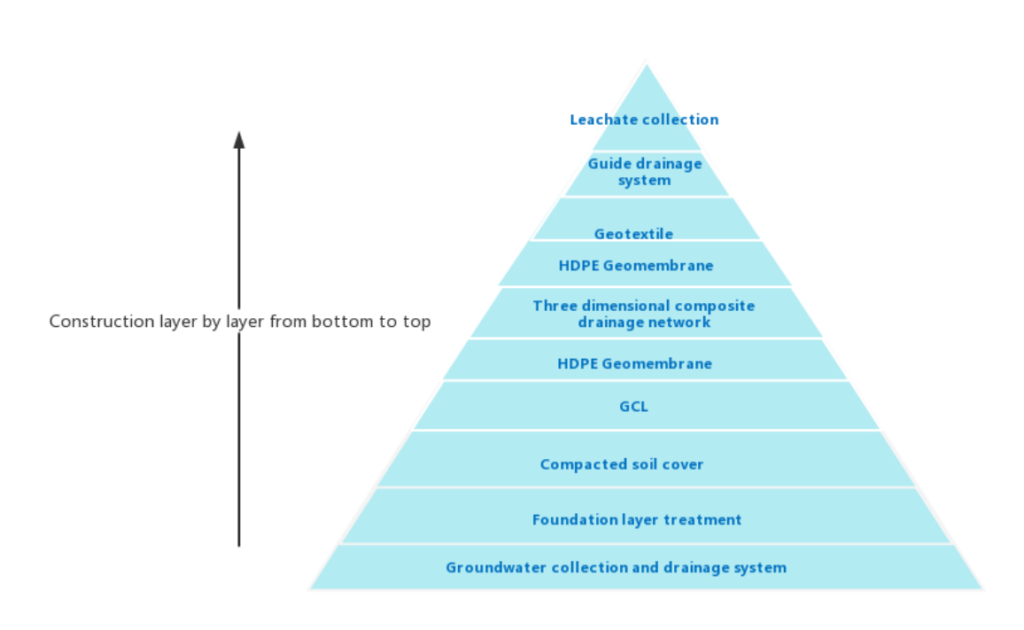

Ⅳ. Construction flow diagram of waste landfill

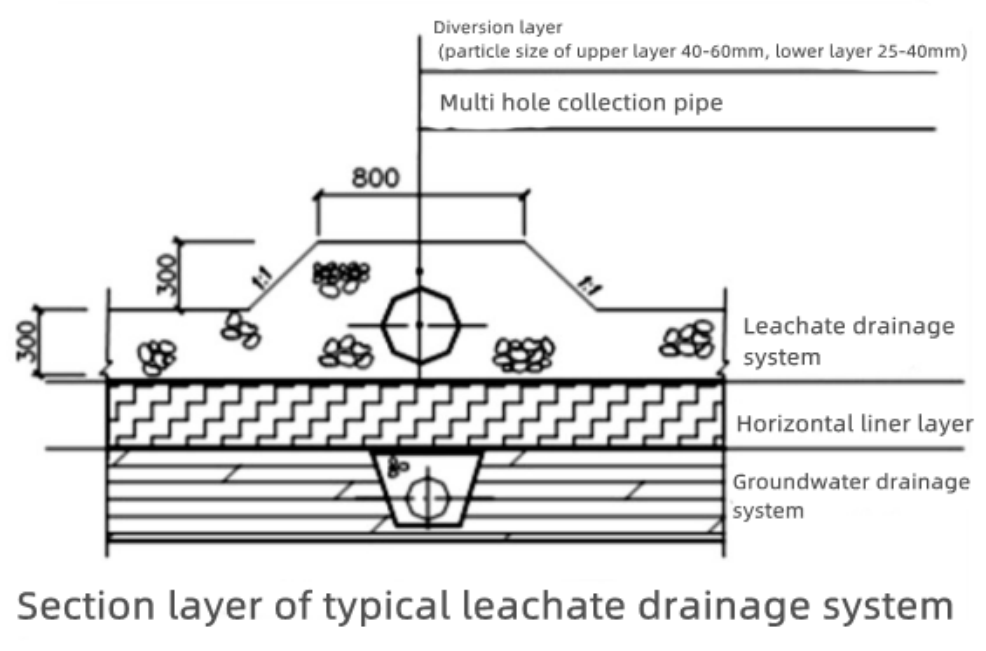

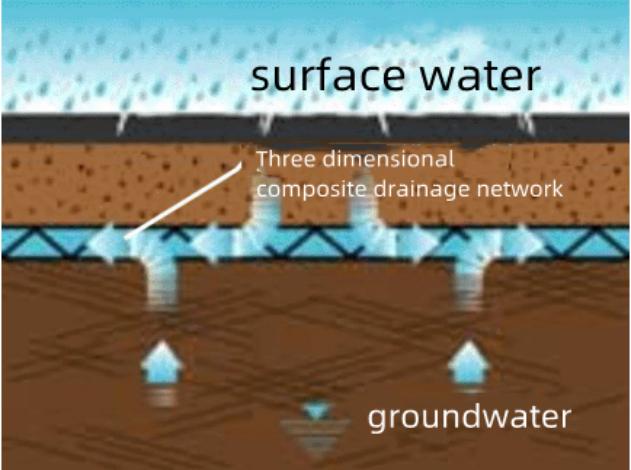

- Groundwater drainage system

1)The landfill site shall be equipped with independent rainwater and groundwater drainage system. The rainwater drainage system shall meet the requirements of rainwater and sewage diversion and direct drainage of catchment water in the non operating area of Yonghe site. The rainwater intrusion into the garbage dump shall be minimized. The groundwater drainage system shall be timely drained to prevent the groundwater from adversely affecting the foundation and anti-seepage system. Its drainage capacity shall match the amount of groundwater generated.。

2) The drainage system shall conform to:

●Timely and effectively collect and discharge groundwater and infiltration surface water;

●Capable of preventing siltation;

●The distance from the top of the groundwater drainage system to the bottom of the foundation layer of the anti-seepage system shall not be less than 1000mm;

●Ensure long-term reliability of groundwater collection and drainage system.

3)Underground water drainage system method: underground blind ditch, gravel diversion layer, and diversion layer of geotechnical composite drainage network.

1)The foundation layer shall be flat, compacted, free of cracks, loose soil, and the surface shall be free of water, stones, tree roots and sharp debris;

2)The site bottom foundation layer of the anti-seepage system shall be designed with longitudinal and transverse gradients according to the requirements for leachate collection and drainage, and the transition to the slope foundation layer shall be smooth, with the compactness not less than 85%;

3)The foundation layer of the surrounding slope of the anti-seepage system shall be structurally stable, and the compactness shall not be less than 85%. When the slope gradient is steeper than 1:2, the slope stability analysis shall be made.

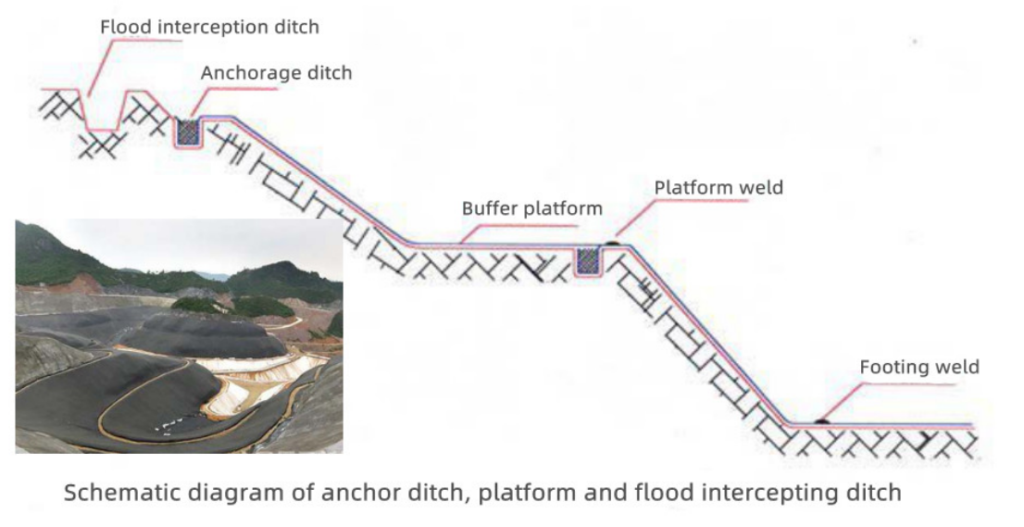

3. Anchorage trench position

4. Compacted soil cover

The soil layer shall be clay. When clay resources are scarce, other types of soil can be used, and the permeability coefficient shall not be greater than 1×10–9m/s;

The soil layer construction shall be compacted layer by layer. The thickness of each compacted layer should be 150-250mm, and the layers should be closely combined;

During the construction of soil layer, 3-5 samples shall be taken from each layer of compacted soil every 500m2 for compaction test.

5. Geosynthetic clay liners

6. Geosynthetic clay liner matters needing attention

Geosynthetic clay liner shall be stored overhead, waterproof, moisture-proof and sun proof;

Geosynthetic clay liner shall not work in rainy and snowy weather;

After the completion of Geosynthetic clay liner construction, effective protective measures shall be taken. No personnel shall wear spiked shoes or tread on Geosynthetic clay liner, and vehicles shall not directly roll on Geosynthetic clay liner.

7. Geosynthetic clay liner overlap joints

- It shall be distributed in a zigzag pattern without cross lapping;

- The slope shall not have horizontal overlap;

- The lap width is 25cm horizontally and 30cm vertically, and the lap joint is sealed with bentonite powder;

- It shall be naturally relaxed and close to the foundation layer, and shall not be folded or suspended;

- The appearance shall be checked at any time to see if there is any defect such as damage and cavity. If any defect is found, repair measures shall be taken in a timely manner. The repair range shall be 200mm larger than the damage range;

- During the construction of special parts such as pipes or building columns, the treatment shall be strengthened.

8. HDPE geomembrane

9. HDPE geomembrane installation

- Before laying HDPE geomembrane, the qualification acceptance certificate of civil works shall be provided;

- Before cutting the geomembrane, its relevant dimensions should be measured accurately, and then cut according to the actual size. Generally, it is not suitable to cut according to the size shown in the drawing. It should be numbered piece by piece and recorded in the special form in detail;

- Geomembrane shall be laid with the minimum number of welds. Generally, the joint length shall be reduced as much as possible in corners and deformed sections.

10. Preparation and welding of geomembrane

- Preparation before laying:

●HDPE geomembrane shall be stored correctly before installation, and its installation position in the general layout shall be marked;

●The laying shall be carried out in place at one time, and shall not be dragged after spreading;

●Allowance shall be made for dimensional changes due to thermal expansion and cold contraction of the material;

●Proper waterproof and drainage measures shall be taken for the protective layer under the membrane.

- Laying and welding:

●After the HDPE film is laid, it shall be welded in time. The horizontal joints shall be minimized when laying on the slope. The overlapping width of the welding joints shall not be less than 10cm. The welding parts shall be free of scratches, dust and other impurities that affect the welding;

●After welding, resume must supervise the welding and inspection of membrane in the whole process.

11. composite drainage net

- The drainage direction of geotextile composite drainage network shall be consistent with the flow direction;

- The composite drainage network on the slope should not have horizontal joints; Lap width is 10cm, fixed with electrical ties;

- During construction in special parts such as pipes or building columns, special treatment shall be carried out to ensure smooth drainage;

- The composite geotextile with drainage mesh core shall cover the mesh core completely, and the geotextile shall be double-layer, with three-dimensional drainage network in the middle;

- In case of damage, the same material shall be used for repair, and the repair range shall be 300mm larger than the damage range;

- During construction, the paved HDPE film shall not be damaged, and the construction machine shall not directly roll on the composite drainage materials.

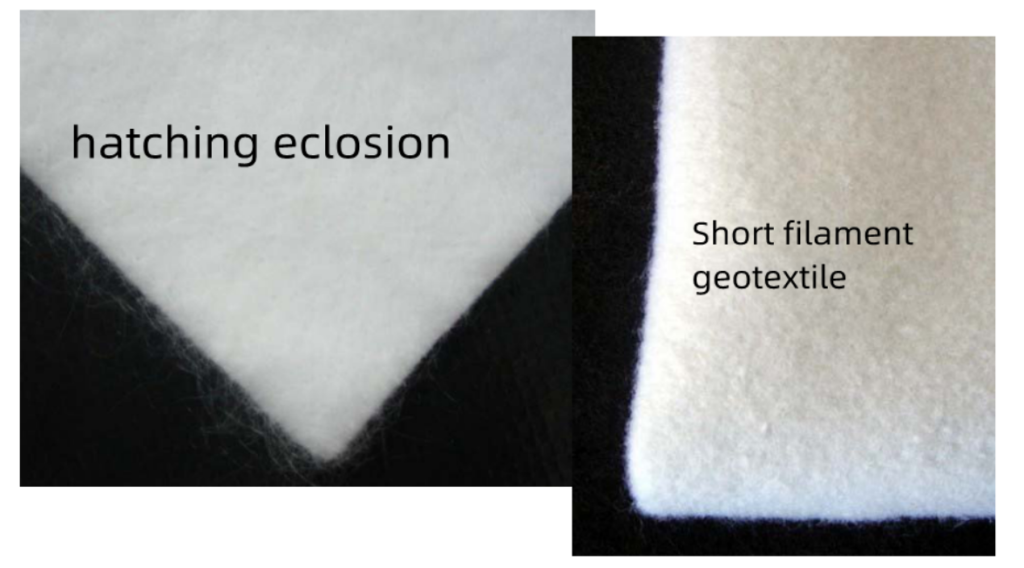

12. nonwoven geotextile

13. nonwoven geotextile

1) The geotextile shall be laid flat, and no stone, soil, water or excessive dust shall enter the geotextile;

2) The geotextile is connected by joints, and the lap width is 75 ± 15mm;

3) The geotextile shall be stitched with UV resistant and chemical resistant polymer wire, and double stitched;

4) For laying on the slope, the geotextile shall be anchored in the anchoring ditch in advance, and then laid down the slope without folding;

5) The laying direction of geotextile on the slope shall be consistent with the slope surface. It is better to lay the geotextile in a whole roll on the slope surface to reduce or avoid horizontal joints;

6) If there are cracks or holes on the geotextile, materials of the same specification shall be used for repair, and the repair range shall be 300mm larger than the damaged perimeter.