Construction conditions of geosynthetic clay liners:

The soil layer under the GCL-3-is finished after being rammed, and the surface is flat, hard, dry and clean.

The compaction degree shall be more than 85%, and the surface shall be flat and smooth. There shall be no rocks and other objects protruding for more than 2cm, and no obvious cavities.

The base surface shall be basically dry without obvious water.

The construction shall be carried out after the foundation and base support layer are validated.

Analyze the material quantity and plan, and draw the laying sequence and cutting diagram of GCL.

Check the appearance quality of GCL, record and repair the found mechanical damage, production trauma, holes and other defects.

The construction of GCL shall be carried out in the weather without rain and snow. In case of rain during construction, GCL shall be covered with plastic film to prevent the GCL from being hydrated in advance.

Big rolls of GCL should be constructed by machines. It also can be laid according to the real situation.

GCL shall be laid in sections and blocks according to the specified sequence and direction.

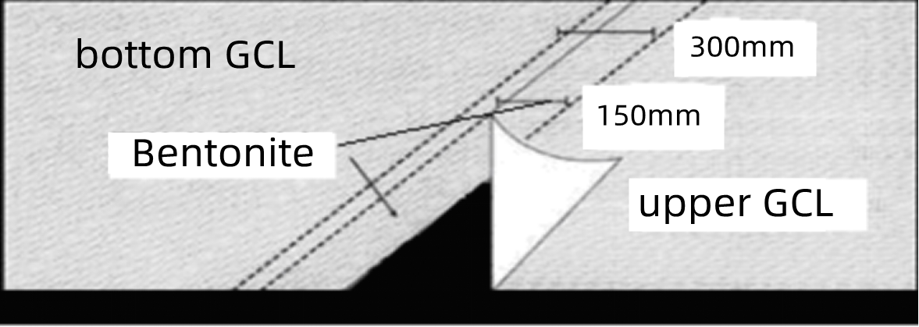

Joints between GCLs should not be in the same line to avoid through joints.

The overlapping surface of GCL shall not be affected by sand, ponding (including dew), etc, to affect overlapping quality.

The nonwoven geotextile side should face the waterside.

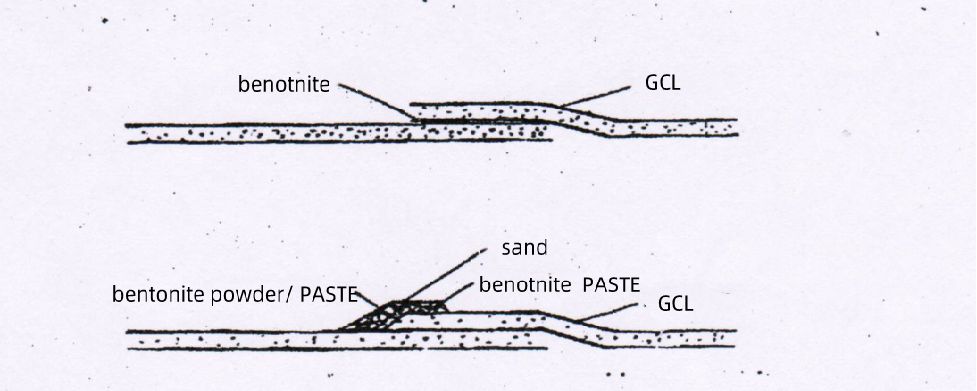

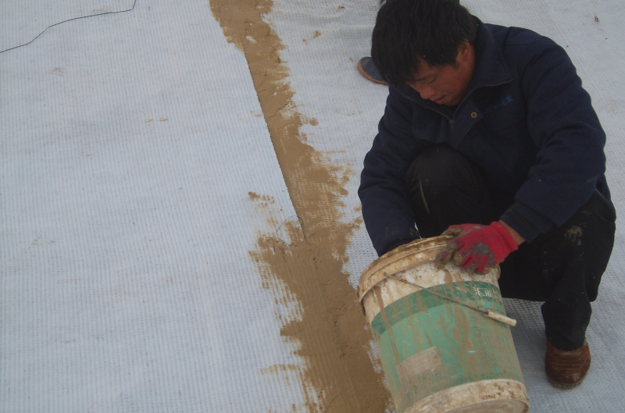

The way to join two GCL-3: Join two pieces of GCL-3 together at first, and turn on the piece above, and then spread the bentonite powder continuously and evenly on the joint area, about 200-300mm width, and the thickness is about 5mm to cover all white area. The weight of bentonite is ≥0.45kg/m.

Then cover the above GCL back, and seal the seam with bentonite powder or bentonite slurry (preparation of bentonite slurry:quantity ratio of bentonite granular and water is 1:6, combine together, and use a force mixer to mix for 3 minutes, stop for 5 minutes, then mix another 3 minutes until bentonite and water are dissolved completely ).

For the details, please check the video below:https://youtu.be/gK-8bum6Yfo