What is geosynthetic clay liners?

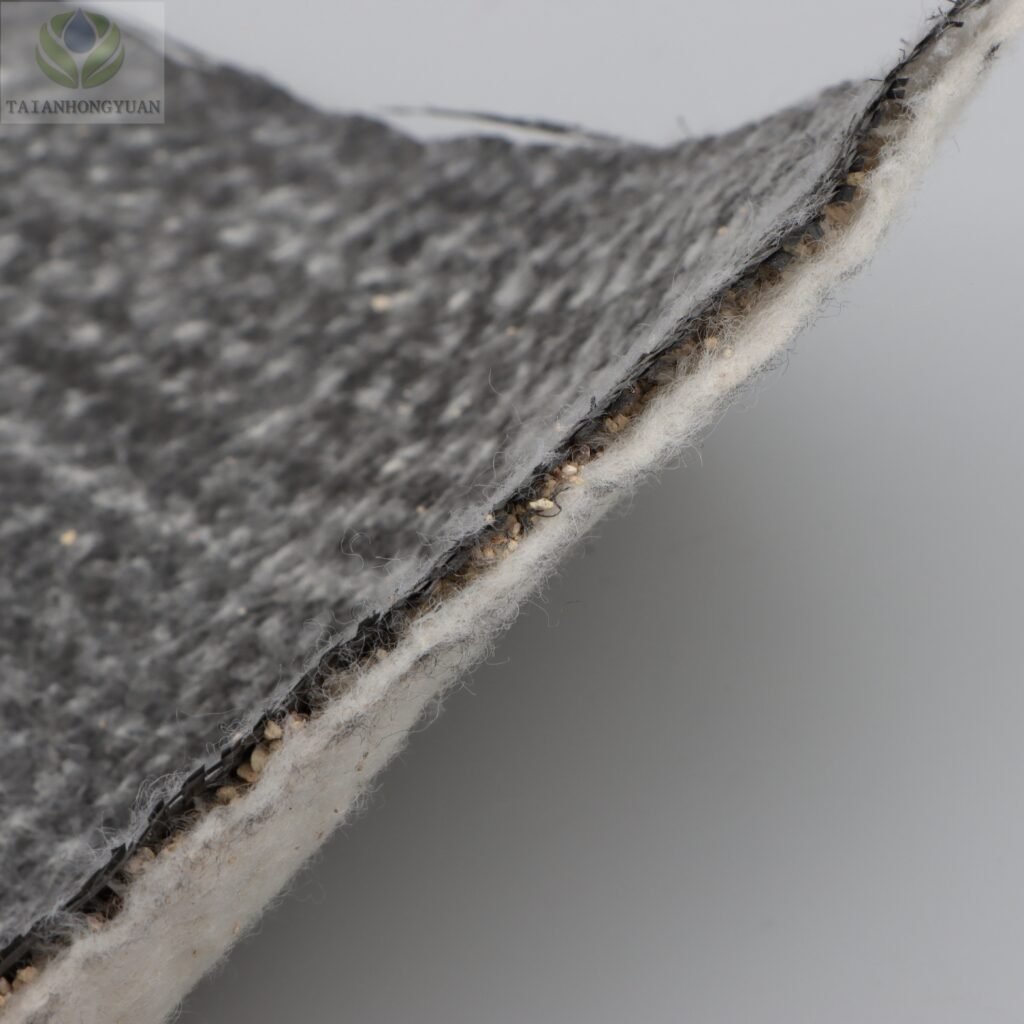

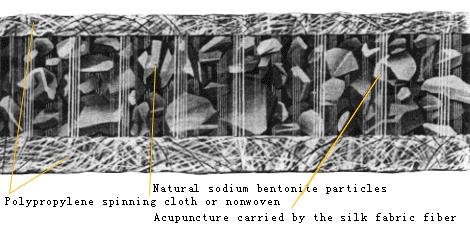

Geosynthetic clay liner is composed of 3 levels. The upper level and the lower level are woven geotextile and non woven textile. The middle level is bentonite grains, which are carefully selected crude and filled in between the two levels after special processing. The bentonite grain in geosynthetic clay liners made by this method does not flow in a fixed direction. It distributes evenly and forms waterproof layer, owning excellent waterproof effect. This GCLs is a kind of new green waterproof materials, which are widely applied in many waterproof construction projects.

Bentonite clay liners can be applied separately, or combined with high density polyethylene (HDPE). Our Geosynthetic clay liner combines the two advantages together, not only containing all the properties of geotextile materials, but also bearing of double waterproof property.

What is the basic structure of geosynthetic clay liner GCL-3?

What is Characters of Geosynthetic clay liners?

Enviroment friendly

Geosynthetic clay liner is made of raw materials of sodium-bentonite, which is natural materials, aging and corrosion seldom happen. It does not cause any injuries and pollution for human and the environment. Sodium bentonite is not only waterproof, but also has good ventilation performance. It can stick up for the exchange of the ecological environment.

Permanent waterproof and excellent performance

Natural sodium bentonite is much more durable than that of the buildings. Sodium bentonite would transform to high density septum under hydro pressure. When The thickness is 3mm, the permeability is below a×10-11/sec(a=1~9), which equals to the density of 100 times of the clay with 30 mm thickness. Water retention performance is evident.

Easy to construct

Bentonite powder, nails and washers are enough for connection and fixation. Construction is not constrained by weather conditions and it could be taken under cold or wet conditions. Bentonite powder is spread on overlap point. When water comes, GCL would be overlapped automatically. It is so far the only material that starts the waterproof effect by water in the world.

Strong self-restore capacity

The integration between waterproof material and its target enables GCL a 20~28 times swelling volume. Even if concrete structure trembles or subsides, the bentonite in GCL would restore the crack of 2mm or below on the concrete structure immediately. Even if the diameter of perforation reaches 30 mm, the restoration will be finished within 15 days completely.

Common Specification of Geosynthetic clay liners

1 Weight(g/m2) ≥5350

2 Thickness(Mm) ≥6.0

3 Expansion index(ml/2g) ≥26

4 Elongation at Break(N/100mm) ≥600

5 Durability of bentonite(ml/2g) ≥20

6 Maximum load elongation (%) ≥10

7 Racking strength(N/10cm) ≥40

8 Permeability coefficient(cm/s) ≤5.0×10-11

9 Water resistant static pressure

(0.4mpa, 1h) No leakage